This update provides an overview of the Small-scale Renewable Energy Scheme (SRES) inspections program for solar batteries installed from 1 July 2025.

The inspections program does not replace electrical safety regulations, or the inspection and compliance programs administered by relevant state and territory authorities. Instead, it complements these laws by using a cross-agency approach to communicate and address areas of concern.

We randomly select installations for inspection from the small-scale technology certificate (STC) applications we receive. We also conduct additional inspections on installations by installers who are found to be non-compliant.

We’ll inspect a statistically significant sample of all solar battery systems that claim STCs. We’ll closely monitor inspection results to identify potential safety issues early and work closely with industry to improve compliance. This includes working with state and territory electrical safety regulators who have the power to enforce standards.

This page will be updated regularly to reflect the latest results.

Overview and safety priorities

As a new inspections program under the SRES, our early results are tracking similar to other state and territory battery inspection programs. It’s too early to draw strong conclusions about the rate of technical compliance under the scheme.

As of 29 January 2026, over 195,000 solar batteries have been installed across Australia since 1 July 2025, equating to 5.4 GWh of installed storage capacity. These solar batteries, distributed across households and businesses, represents a rapid acceleration of progress towards Australia’s target of 82% renewables by 2030.

Safety is a priority

By certifying the installation as compliant, installers are confirming that the installation is safe and eligible under the SRES. Where our inspections find unsafe and non-compliant systems, we won’t hesitate to use our compliance powers. This can result in installers being removed from the SRES. Our established systems that have supported over 4.2 million rooftop solar systems are now working to successfully support the growing number of solar battery installations. This includes identifying areas of non-compliance quickly and allowing us to drive continuous improvement through:

- ongoing and targeted education for installers in collaboration with Solar Accreditation Australia based on the latest inspection findings

- working with state and territory electrical safety regulators to update and refine the inspections program to better reflect emerging risks

- taking appropriate enforcement action against installers where necessary, including to declare installers ineligible to participate in the SRES if installations repeatedly fail to meet requirements.

Installed products must be on the Clean Energy Council’s approved product lists and meet relevant standards to be eligible under the SRES. The ongoing safety of approved products is the responsibility of the CEC, state and territory regulators and, where required, the Australian Competition and Consumer Commission (ACCC) who manages a national recall system for electrical products.

As of 17 December 2025, one eligible product under the SRES has been recalled. The Australian Competition and Consumer Commission (ACCC) issued a voluntary electrical safety recall for Sigenergy single phase 8/10/12 kW energy controllers on 19 November 2025. Sigenergy is committed to rectifying this issue and is working with the ACCC, state and territory electrical safety regulators and installers to ensure the ongoing safety of the affected product.

Inspection results

As of 29 January 2026, we have conducted 726 solar battery inspections on installations that have received STCs. Of these inspections, 238 have been finalised.

As of 29 January 2025, inspections have been carried out across 5 states and includes:

- 236 inspections in VIC

- 228 inspections in QLD

- 98 inspections in NSW

- 87 inspections in SA

- 77 inspections in WA.

Inspections program checklist items

The inspections program uses a checklist developed with industry experts. The checklist items reflect regulations, standards and industry requirements. The checklist has over 90 items* that review compliance and safety.

In total, our inspectors have reported on over 59,291 checklist items across the 726 inspections.

Of these:

- 1.3% of checklist items have required rectification

- 5.3% of checklist items have been identified as areas for improvement

- 93.4% of checklist items have been found compliant.

* Not all checklist items apply to every installation. Relevant checklist items depend on the installation and battery type. Some installations may have more than one item marked.

How to use the graphs on this page

The graphs on this page are interactive. To see more detailed information for these graphs:

- hover your cursor over the areas and data points to see more information in a pop-up

- click the legend labels below the graphs to change what data is displayed in the graph

- click the menu icon in the top right corner of each graph for more options, including downloading source data or images of the graph as it is displayed on the screen.

Checklist items by ratings for all inspections

Checklist criteria results by category

Description

This graph shows a breakdown of checklist items per category.

Numbers less than 1% may not be visible.

Small print

Compliant checklist items comply with installation requirements.

Recommendation for improvement checklist items can be improved but are not required to be rectified – installers are encouraged to change their processes to address this for future installations.

Substandard (technical non-compliance) – rectification required checklist items must be rectified by the installer – system owners should contact their installer to arrange for these items to be fixed.

Unsafe – rectification required checklist items must be rectified before the system can be switched back on.

Installation ratings

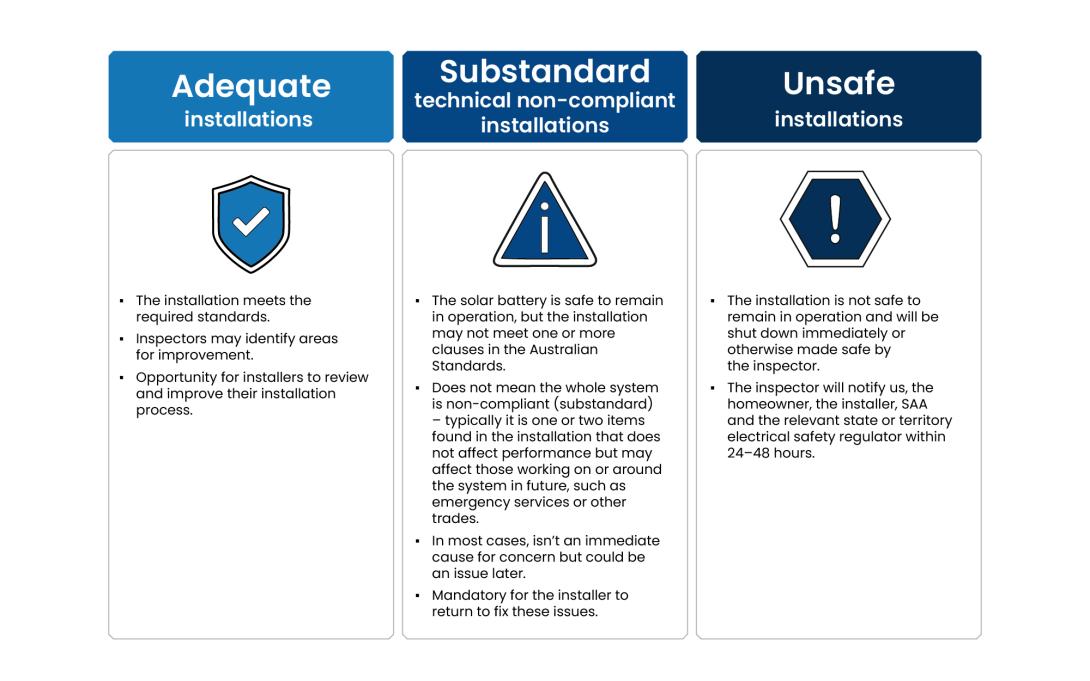

Installations are rated as adequate, substandard – technical non-compliant or unsafe.

Based on all inspections, the ratings are:

- 0.9% have been found unsafe.

- 62.0% have been found substandard – technical non-compliant but were safe to remain in operation.

- 37.0% have been found adequate and safe.

No installations had issues with the solar battery itself. Instead, all issues were due to non-compliant installation practices and substandard workmanship.

The issues leading to the unsafe installations included:

Wiring

Loose connections in pre-assembled battery systems and associated wiring with signs of heat.

Protections

Neutral continuity was not maintained for all circuits operating on an alternative supply.

The most common reason for installations to have technical non-compliance was due to labelling issues.

Checklist criteria requiring rectification

Description

This graph shows checklist categories requiring rectification by quarter.

Small print

* Data for this quarter is not yet complete and may change once finalised. The finalised data will be published in future updates.

Results for future quarters will be added once available.

The most common labelling issues for substandard – technical non-compliant installations include:

Incorrect or missing warning label

A compliant warning label must be installed at the main switchboard and all intermediate distribution boards to show a multimode inverter with alternative supply has been installed and to follow the shutdown procedure for safe isolation. The sign must also include the text ‘Neutral and earth circuits may be live under fault conditions’.

Incorrect labelling of backed-up circuits

Battery systems may have a back-up supply feature, leaving all or partial electrical circuits energised. Some battery systems have a time delay before re-energising back-up circuits after the main switch is turned off.

To reduce the risk of electric shock, it’s important that this is clearly labelled so that electricians or other trades are aware before they begin work. Backed-up circuits must also be grouped together to make it easier for anyone working on the switchboard to identify any sources of back-up power.Incorrect labelling for emergency services

A green reflector sign with the letters ‘ES’ to signify energy storage must be installed on or next to the meter box and switchboard so that emergency services are aware there is a solar battery connected to the solar PV system at the property. This is important for emergency services to be aware of during an emergency response.

The most common wiring issue for substandard – technical non-compliant installations is:

Incorrectly configured or missing residual current device (RCD)

RCDs are designed to protect against electric shock and fire by cutting off power when an electrical fault occurs. RCDs must be correctly configured and installed wherever alternate supply circuits exist.

System inspection findings by state

Next steps

During these early stages of the program, we’ll closely monitor installers’ actions to ensure they understand what’s required and to make improvements as needed.

We are committed to working with industry to ensure safe, high-quality installations that deliver confidence to households and businesses. To achieve this, we are:

- providing comprehensive briefings on inspection findings to SAA and state and territory electrical safety regulators, who have responsibility to enforce standards

- analysing inspection findings and identifying opportunities for improvement to support state and territory regulators to improve compliance in their own jurisdictions

- communicating regularly with installers and manufactures to ensure that safety issues are quickly identified and escalated

- working with SAA to improve training including developing additional mandatory training modules based on non-compliance trends

- implementing new photo evidence requirements for solar battery installations to address critical labelling issues, commencing 1 March 2026

- progressively expanding our inspections program to inspect a larger number of installations in line with the growth of solar battery installations across Australia

- increasing inspections on higher-risk installations based on previous inspection results.

We, along with the Department of Climate Change, Energy, the Environment and Water, are focused on continuous improvement in solar battery installation compliance.