How a wastewater project is set up and run is critical for calculating the amount of abatement that has occurred and how many ACCUs may be issued for a project. Parts 3 and 4 of the method and explanatory statement describe in detail how to set up a project and how to calculate the volume of carbon stored, as well as the net abatement that has occurred.

Setting up and running a wastewater project can be divided into the following parts. Each part below refers to the relevant sections of the method and explanatory statement, which explain the project in more detail.

Remember to download a copy of the explanatory statement to read along with the wastewater method. The explanatory statement provides further detail and is an important document for interpreting and understanding the method.

Establish the project

Setting up and running a wastewater project involves replacing a suitable lagoon (Section 9) with an anaerobic digester (Section 10). The biogas from the anaerobic digester is sent to the combustion device (Section 11).

Choose a suitable lagoon to be replaced

You can replace anaerobic lagoons treating any combination of domestic, commercial or industrial waste. However, they must be more than two metres deep to ensure that they have the same methane-generating output as anaerobic digesters. This ensures that no extra methane is generated by simply replacing a shallower open anaerobic lagoon with an anaerobic digester.

You need to provide evidence of the type and source of wastewater used in the 12 months before you apply to run a project. The wastewater’s source might be the physical location where it is generated – for example, a housing development – or a specific activity or facility that generates the wastewater, such as a milk processing plant that produces industrial wastewater.

Choose an appropriate digester

An anaerobic digester must capture biogas that results from the treatment of water in the digester. It must promote anaerobic digestion, which can be done in one of two ways. The first is to cover an existing open lagoon. In this case, you cannot add additional stirring or heating elements compared with what was in the original open lagoon. Alternatively, you can construct a purpose-built closed vessel, known as an engineered biodigester, which has heating and stirring features.

The digester must also have a mechanism by which to collect biogas, and equipment to transfer the biogas to a combustion device.

Choose an appropriate combustion device

This method includes the use of a new or existing flare, boiler or internal combustion engine as the combustion device. If the combustion device you choose is not one of these, then it requires approval by the Clean Energy Regulator before it can be used. To be approved, the device must destroy at least 98% of the methane in the biogas, and must be able to be monitored on a minute-by-minute basis.

Calculate project baseline

The project baseline is an estimate of emissions that would have been released to the atmosphere if the project did not occur. For a wastewater project, the baseline emissions are those that would have resulted if the eligible wastewater was treated in a deep open anaerobic lagoon instead of an anaerobic digester. Eligible wastewater means domestic or commercial wastewater, or industrial wastewater, from an historical source for the project.

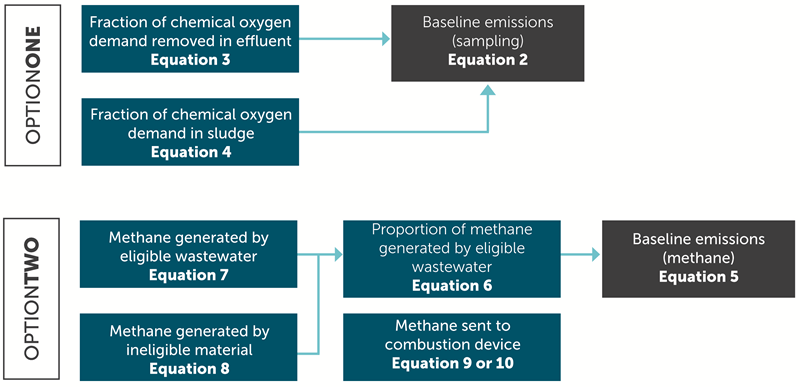

There are two ways to calculate the baseline for a wastewater project (Part 4, Division 3 in the method). You can measure the amount of organic material in the wastewater that would have been treated (Subdivision B), or you can measure the amount of methane sent to the combustion device (Subdivision C).

Option 1: Measuring the amount of organic material

The first option (Sections 18–24 in the method) calculates baseline methane emissions by determining the amount of organic material in the eligible wastewater that would have been treated in the original deep open anaerobic lagoon and subtracting the amount of organic material in the effluent and sludge, which represent what was not treated. The amount of organic material is measured in units of tonnes of chemical oxygen demand, or COD (see Box 1).

To use this option, you must have previously taken samples of wastewater from the lagoon before replacing it with an anaerobic digester. This is known in the method as historical sampling.

Historical sampling may be conducted monthly over a one-year period, or daily over 10 consecutive days. The sampling must have begun no more than 18 months before the project application date, to ensure that the samples represent recent treatment in the deep open anaerobic lagoon. The amount of COD in the effluent and sludge it is also adjusted based on whether 10-day sampling or one-year sampling was done. This is because a longer sampling time provides greater certainty in the COD results.

Box 1: Chemical oxygen demand (COD)

COD is a measure of water quality. It represents the amount of oxygen consumed by a solution (often expressed in milligrams per litre). COD is used to indirectly measure the amount of organic compounds in water. For example, to determine the amount of organic pollutants in wastewater.

To calculate the baseline emissions, the first step is to determine the amount of COD in the influent via monitoring. Then, determine the fraction of COD that would have been removed in the effluent using Equation 3 (Figure 1). The fraction of COD that would have been removed in sludge is calculated either using default values or by Equation 4 (Figure 1), depending on the sampling regime chosen (Section 22 in the method).

Equation 2 (Figure 1) is then used to calculate the baseline by subtracting the amount of COD in the effluent and sludge from the amount of COD in the influent.

All of the factors used for the final calculations are described in Sections 18–24 of the method.

Option 2: Measuring the amount of methane

The second option (Sections 25–30 in the method) involves calculating the amount of methane generated from the treatment of eligible wastewater that was sent to combustion devices (Equation 5, Figure 1).

As part of Equation 5, an adjustment factor is applied to reflect the fact that an engineered biodigester will generate more methane than a deep open anaerobic lagoon (Section 25). This is due to additional features such as heating and stirring, which increase methane generation. The adjustment factor depends on whether a covered lagoon or an engineered biodigester is used.

Only methane generated by eligible wastewater is considered when using this option to calculate the baseline (Equations 6–8, Figure 1). These calculations are described in Sections 26–28 of the method. When calculating Equations 7 and 8, you must take into account the maximum methane-producing capacities for different types of material in the wastewater. You may either monitor this as described in Section 45 of the method, or you can use the default values given in Schedule 1 of the method.

Section 30 sets out two approaches to calculate the methane sent to combustion device, depending on whether or not the device is an internal combustion engine (Equations 9 and 10, Figure 1).

Figure 1: Calculating your project baseline

The wastewater method contains two options for calculating the project baseline: one that involves sampling to measure the amount of organic material in the wastewater that would have been treated (top), or one that involves measuring the amount of methane sent to a combustion device.

Choosing which option to use

If you have undertaken historical sampling for the purposes of working out baseline emissions, then you can choose to use either option above. If not, then you can only use option 2. If you do have historical information, but it does not meet the requirements specified in the method (see Section 45), then you must also use option 2. Whichever method you use for the first reporting period must also be used for subsequent reporting periods (Section 17 in the method).

Calculate emissions from the project

Every project needs to take into account emissions that arise from running it (see Part 4, Division 4 in the method). This is to ensure that these emissions are included in calculations that determine the net CO2-e abatement for a reporting period and crediting period.

The greenhouse gases that are accounted for in the calculations are listed in Section 13 of the method. For an explanation of the sources of greenhouse gas that are excluded from the calculations, see Section 13 in the explanatory statement.

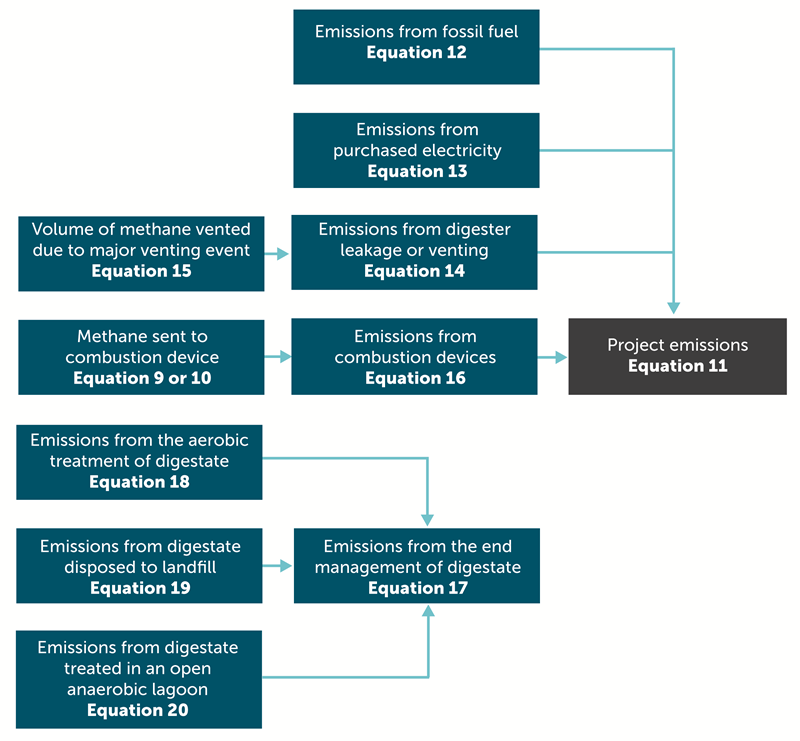

Wastewater project emissions are calculated using Equation 11 (Figure 2). This equation takes into account emissions from:

- fuel use (Section 33)

- electricity use (Section 34)

- the anaerobic digester (Sections 35 and 36)

- the combustion device (Section 37), and

- the end management of the digestate (the solid material that remains after wastewater treatment; Sections 38–41).

The quantity of solid, liquid and gas fuel used during the reporting period should be monitored so that emissions can be calculated for each fossil fuel used and for each greenhouse gas emitted (Equation 12, Figure 2). Emissions from purchased electricity are calculated using Equation 13 (Figure 2).

Emissions from the anaerobic digester can arise from one of two situations. There can be a small amount of methane leakage during normal operations (Equation 14, Figure 2), or there can be a major venting event, such as during maintenance procedures (Equation 15, Figure 2), where biogas stored in the system is released to the atmosphere. Whether you used Subdivision B or C to calculate baseline emissions will determine how you calculate emissions from the digester, as described in Section 35 of the method.

To calculate methane and nitrous oxide emissions released as a result of methane combustion, use Equation 16 (Figure 2).

The emissions from the end management of digestate are calculated using Equation 17 (Figure 2). This equation adds together the emissions from the different ways which the digestate could be treated. These are:

- aerobic treatment (Equation 18, Section 39)

- disposal to landfill (Equation 19, Section 40), or

- in an open lagoon (Equation 20, Section 41).

If the digestate is not treated in one of these ways as described in the method, then digestate emissions are taken to be zero.

Figure 2: Calculating your project emissions

Wastewater project emissions take into account fuel and electricity use, the anaerobic digester, the combustion device and the end management of digestate.

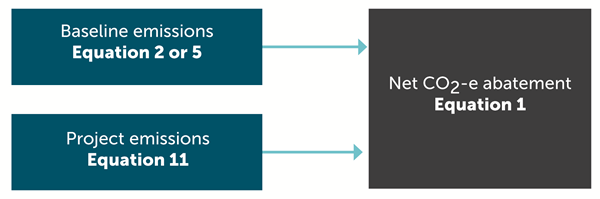

Calculate the net amount of abatement and number of ACCUs

This is the final step in the calculations to determine the number of ACCUs that may be issued for a reporting period. At this stage the total emissions avoided by the project are calculated and then converted to tonnes of CO2-e.

The net amount of abatement for the reporting period (Equation 1, Figure 3) is calculated by subtracting the total project emissions (Equation 11, Figure 3) from the baseline emissions (Equation 2 or Equation 5, depending on how the baseline was calculated in Figure 1).

If the amount worked out for Equation 1 is less than zero – that is, if the project creates more emissions than would have been generated without it – then the carbon dioxide equivalent net abatement amount for the reporting period is taken to be zero.

What's CO2-e?

CO2-e (carbon dioxide equivalent) is a measure of the warming effect of different greenhouse gases that allows them to be compared to the equivalent amount of carbon dioxide. It refers to the amount of carbon dioxide that would give the same warming effect as each greenhouse gas that is emitted or stored by an activity.

Figure 3: Calculating your project’s net amount of abatement

The net amount of abatement is calculated by subtracting project emissions from baseline emissions for the reporting period.

Wastewater project case study

An abattoir currently uses an open anaerobic lagoon to treat the effluent that it generates. The biogas produced by the lagoon contains 55 to 70 per cent methane. The abattoir realises that it is contributing to global warming and wants to reduce its emissions through a wastewater project. As an added incentive, it can claim ACCUs.

The first thing the abattoir does is check the existing lagoon. As it is more than two metres deep, the lagoon qualifies for replacement in a Wastewater project. The abattoir also needs evidence of the kind and source of wastewater treated over the previous 12 months, to ensure that emissions reductions are genuine. Fortunately, it has the relevant records.

Next, the abattoir chooses a suitable anaerobic digester. Digesters create biogas (gas) and digestate (solid mass), but only digesters that can capture the biogas and transfer it to a combustion device are permitted. Appropriate digesters, such as a covered lagoon and combustion devices such as an internal combustion engine are described in the method.

To determine how many ACCUs the abattoir is entitled to, it first calculates its baseline emissions. As the abattoir had not taken samples for this purpose, the baseline is equivalent to the amount of methane destroyed by the combustion device, which is relatively straightforward to work out. The second calculation is the project’s emissions—those that the wastewater project is creating through energy use, the combustion device and management of the digestate. The difference between the baseline and project emissions gives the abattoir the amount of emissions that it has stopped from entering the atmosphere (also known as the abatement amount).

The abattoir calculates baseline emissions to be 4053 tonnes of CO2-e and project emissions to be 1507 tonnes of CO2-e. Therefore, the amount of abatement is 2546 tonnes of CO2-e, which is equivalent to 2546 ACCUs. The abattoir is pleased with the result and decides to sell its ACCUs to generate additional income.